Mini-Projects

These are small projects and models that I have made. They are listed newest to last.

Fasteners that are completely dictated by input variables. Based off Accu fasteners for dimensions, it'll allow the user to quickly create new dimensionally accurate fasteners, by simplyl adjusting the variables in one place which proceeds to automatically adjust the rest of the model.. There are two toggles for level of detail. The threads are custom sweep cuts and are ISO-accurate, due to using official ISO documentation. All detailing features adjust automatically to the size of the fastener.

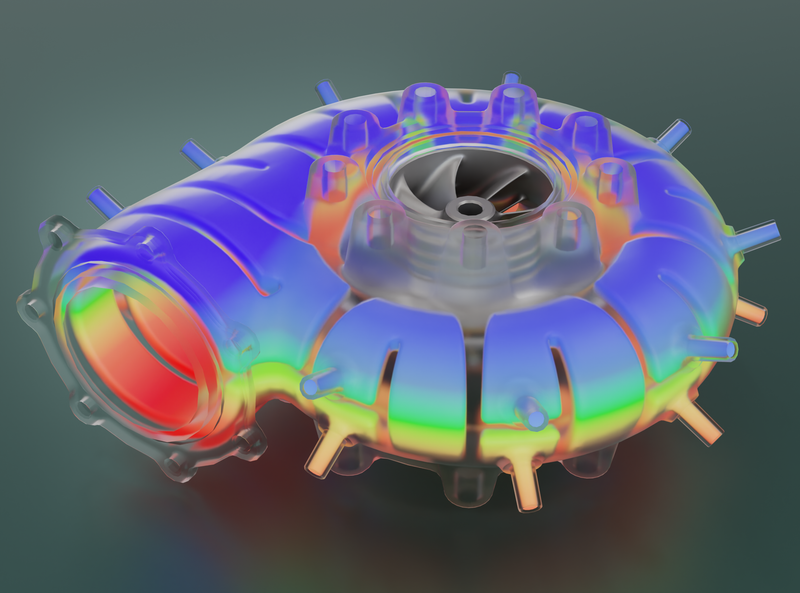

Read More3D-printed from nylon, this water-cooled pump would be used with boiling water as a working fluid. Whilst this project was ultimately no longer needed by the team, the cost and manufacturing restraints created unique solutions to the heat issue. The CAD techniques and ideation behind the cooling channels and the pump design was a fun challenge and expanded my skillset. These ideas of integrated cooling channels, made possible by 3D-printing, can be applied to numerous other applications.

Read MoreThis is the stage where I start making the shift away from SOLIDWOKRS Visualize and begin rendering projects in Blender instead.

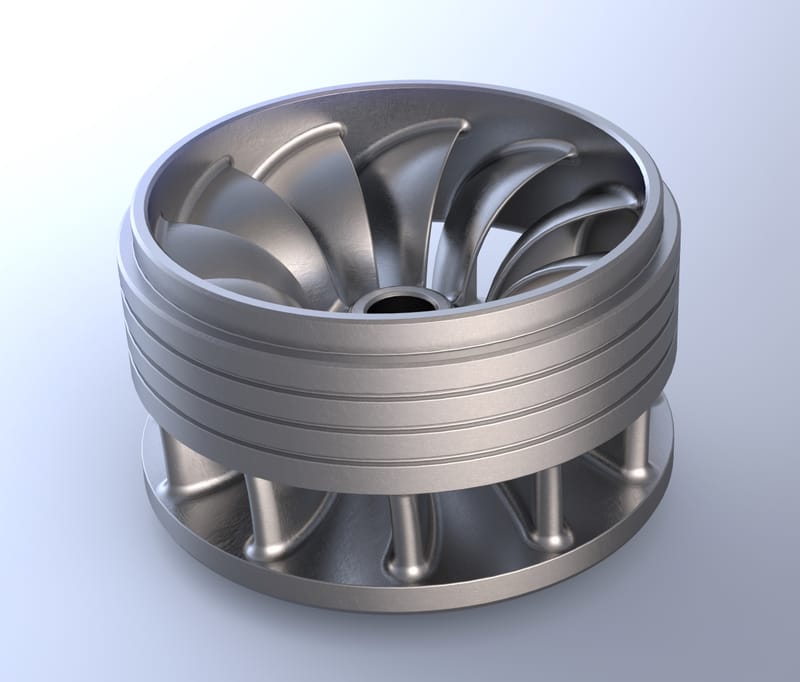

Read MoreThe Francis turbine runner is a fair complex piece of geometry and being able to model this helped me learn how to use certain features in Solidworks - Boundary boss extrude in particular.

Read MoreJust a short gear animation of a simple 2:1 gear ratio. This was done quickly in 720p.

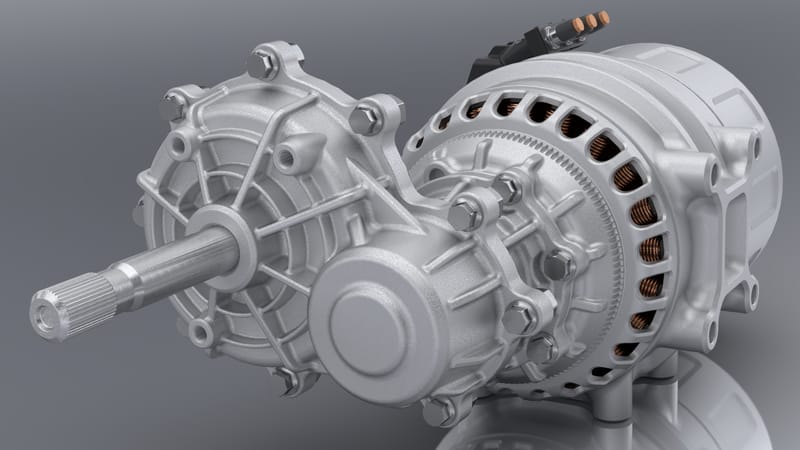

Read MoreOriginally, just wanted to make a simple 2:1 gear ratio animation for my A level project but ended up making a gearbox body shell and an electric motor to accompany it.

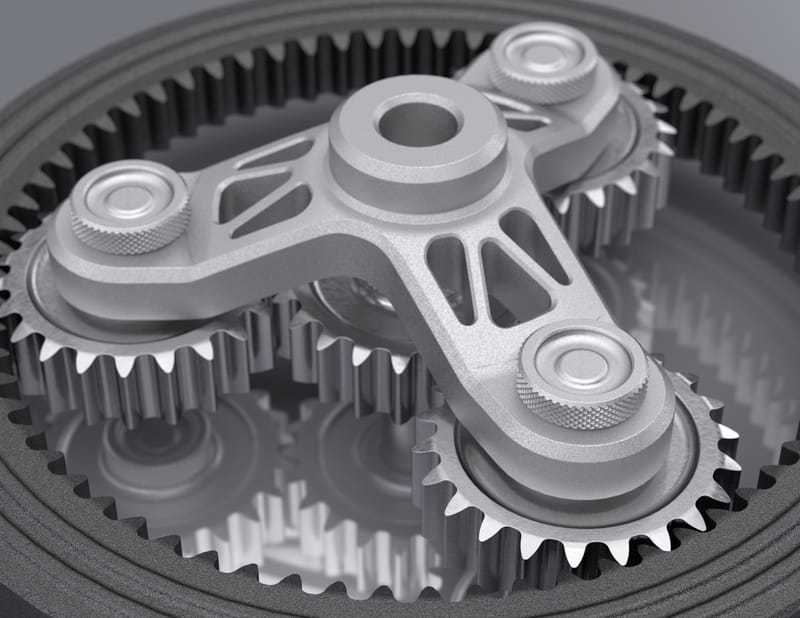

Read MoreI animated planetary gears for my A-level project.

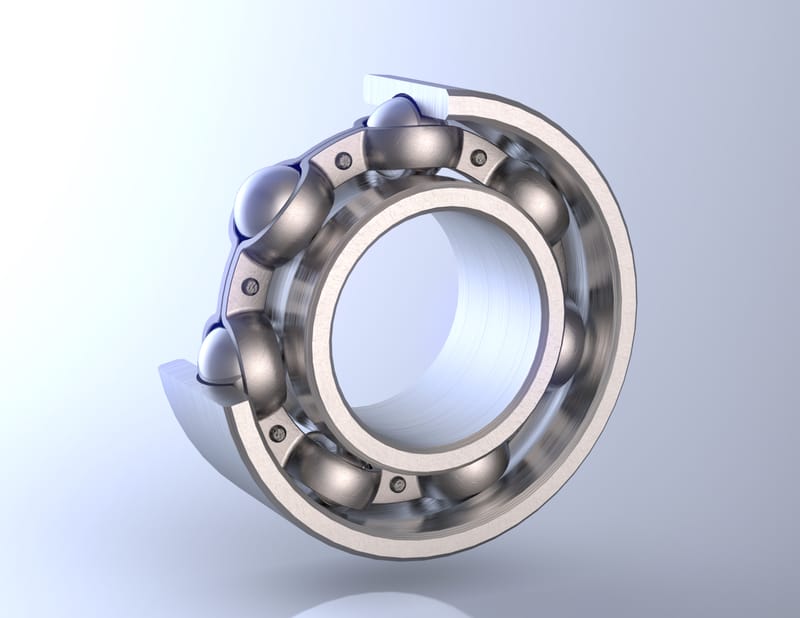

Read MoreSmall radial ball bearing that was used in the RC car differential. The ball bearing cage uses a stamped metal design. Trying to get the stamped piece to perfectly fit with the ball bearings was possibly the most difficult element of this model.

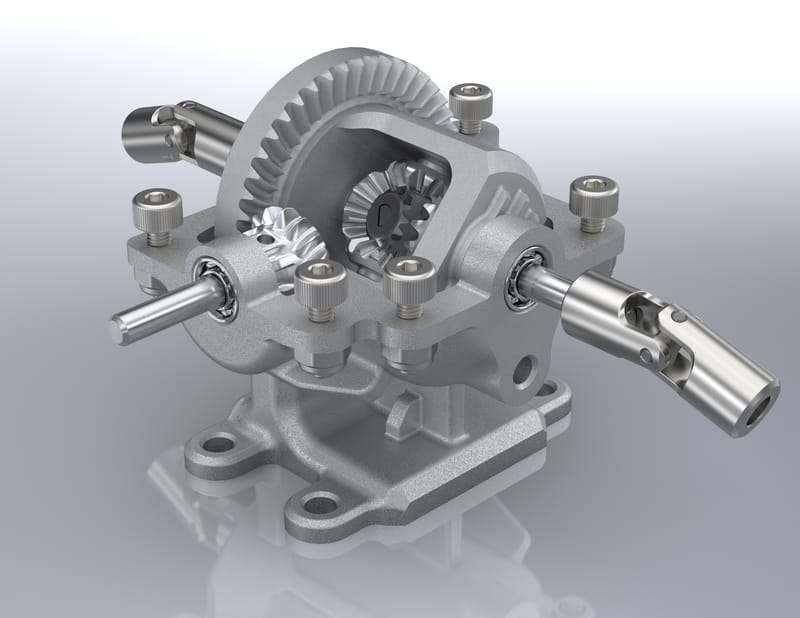

Read MoreI designed this differential for a RC car project that my friend and I were doing. This is a working differential allowing for one wheel to go slower than the other. The gear ratio of the differential is 1:3.

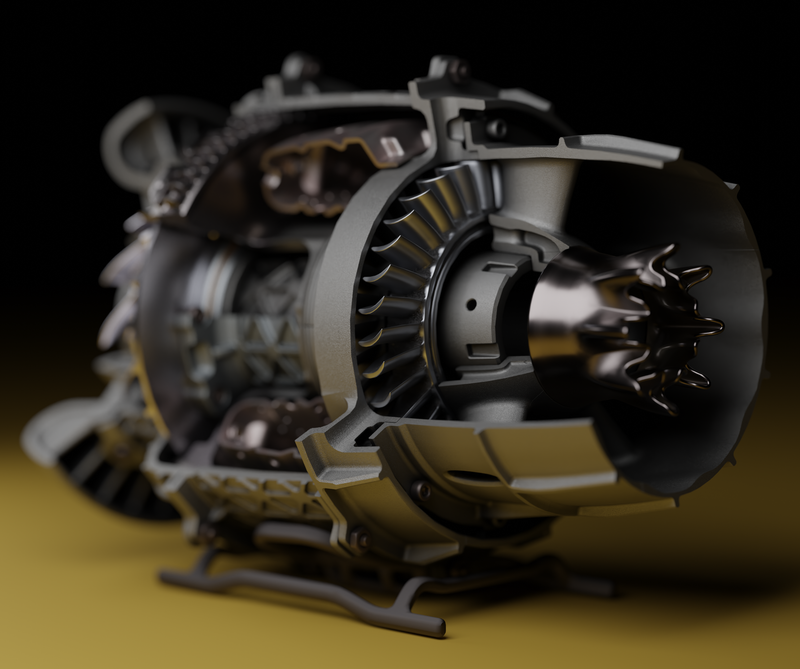

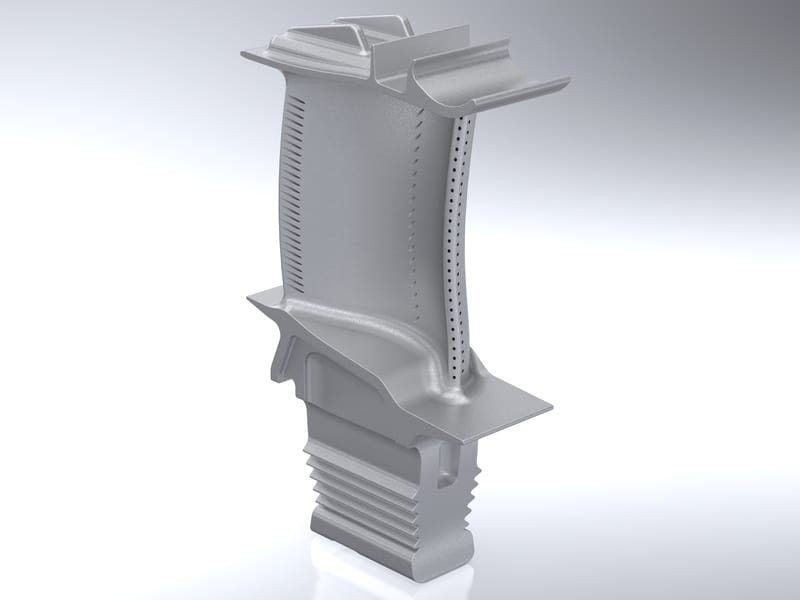

Read MoreA simple turbine blade with film air cooling.

Read MoreThis multi-tool pliers is complete with 18 different tools all ensuring that you'll be carrying anything you could possibly need to use.

Read MoreSimply a test model that I quickly put together to learn how to make a knurled surface and to play around with lighting in SOLIDWORKS Visualize.

Read More