My Engineering Portfolio

This is simply a place where I can show recent projects and engineering related work that I have done.

About

My primary interest is turbomachinery which you'll find is a common theme throughout my portfolio. They're intricately amazing and complex machines and I wish to be in the forefront of its cutting edge development.

Projects

These are my larger scale projects that I have completed including those conducted both in and outside of school. A number of these have also proceeded further than just a virtual CAD model and have been manufactured and tested.

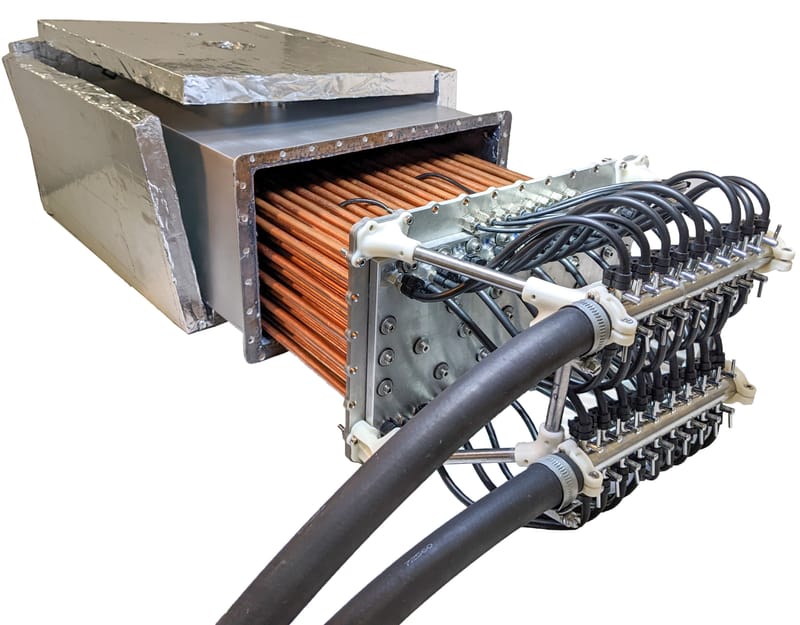

The aim of the project was to modify the engine cooling system to have a heat exchanger to recover heat and then consequently store this in a PCM thermal battery. The heat from this battery can be used for warming up engine in cold starts and for cabin heating & aircon - all of which help reduce the emissions of the vehicle. This is aimed at combustion vehicles, but has possible applications in EVs too. Overall, this project was successful in creating a prototype heat storage unit. This project scored the highest in the class.

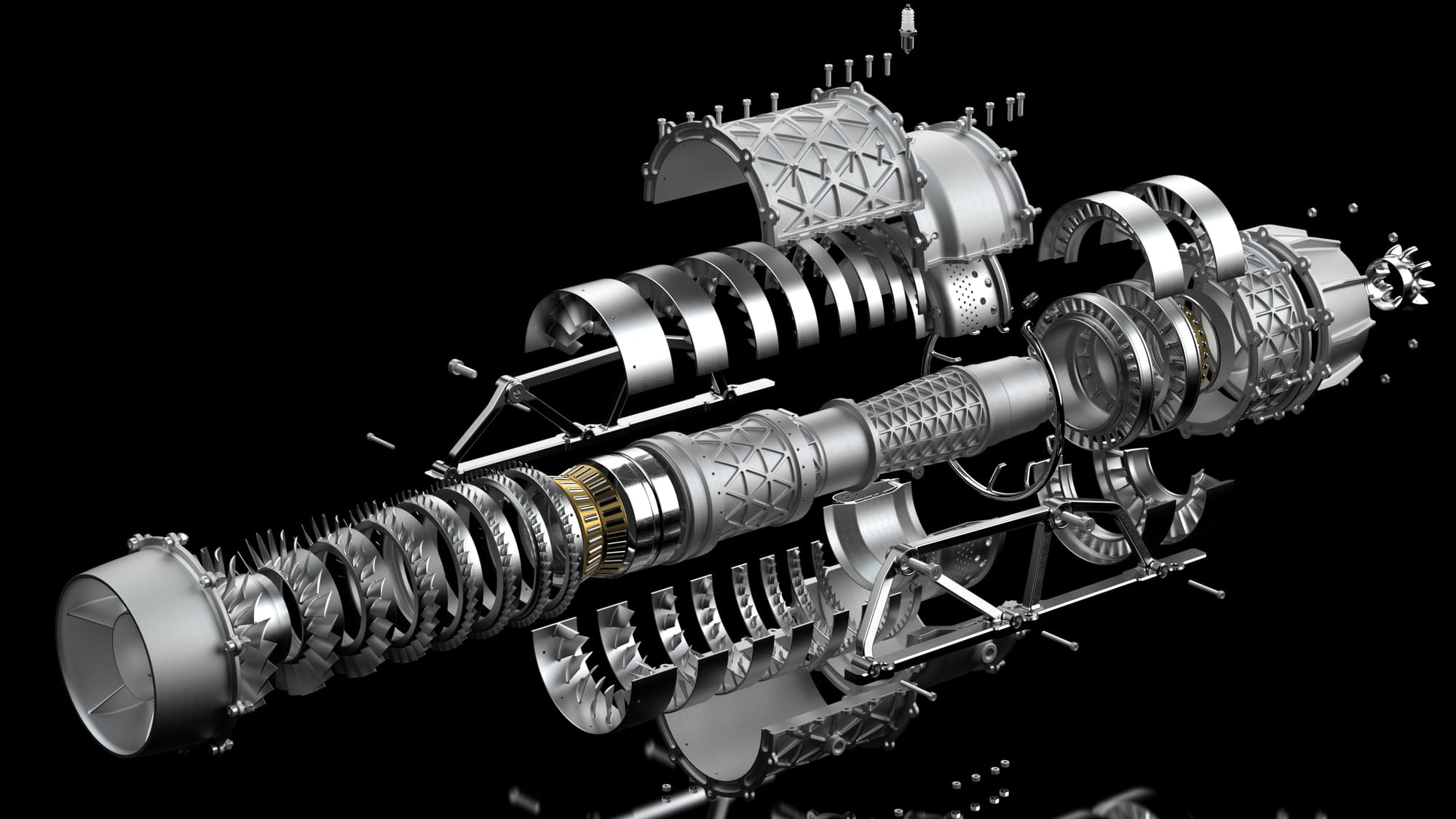

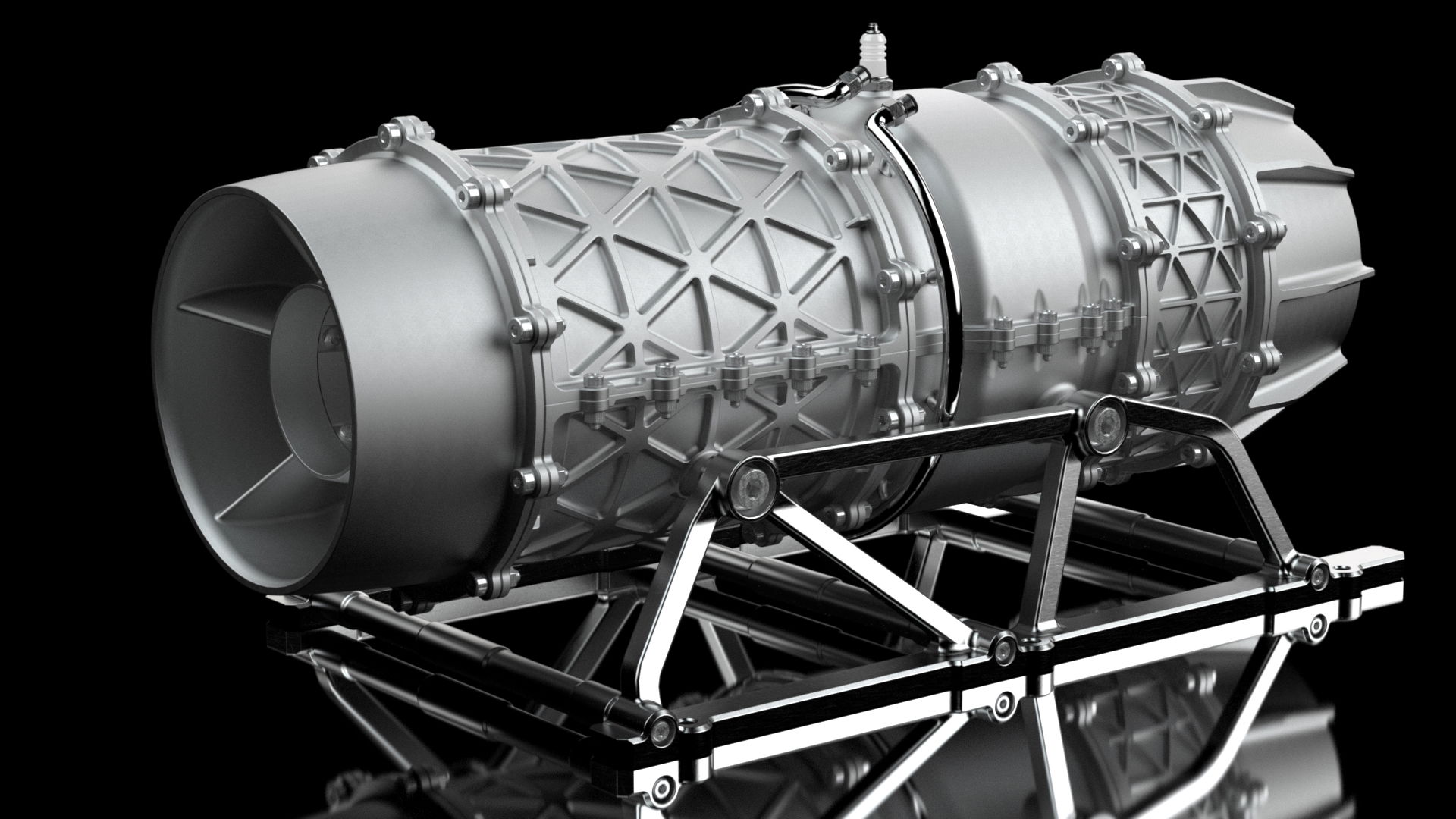

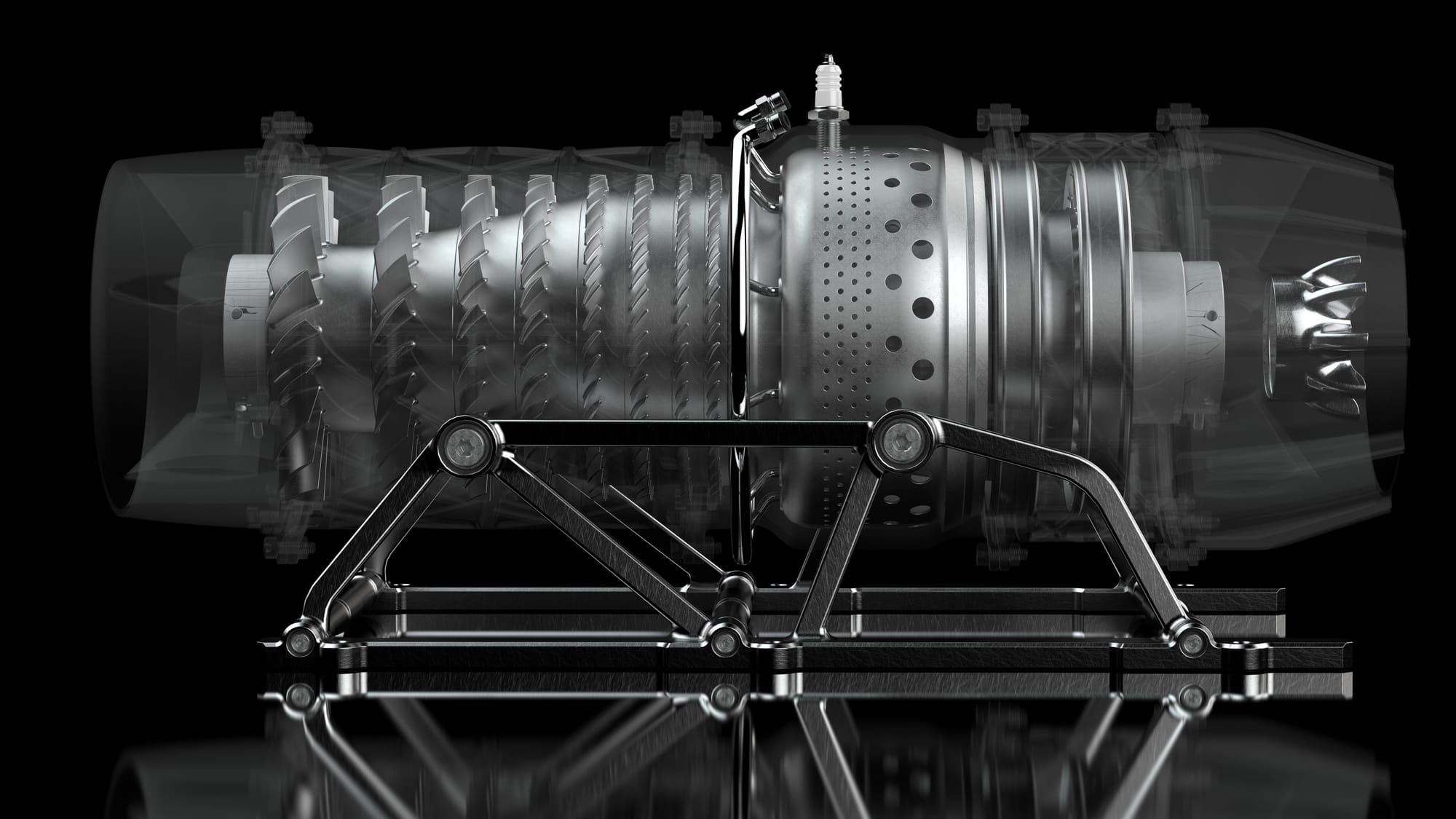

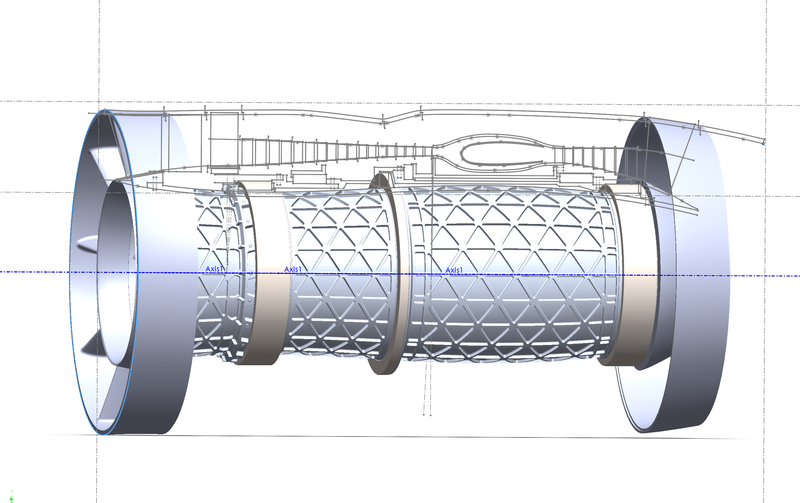

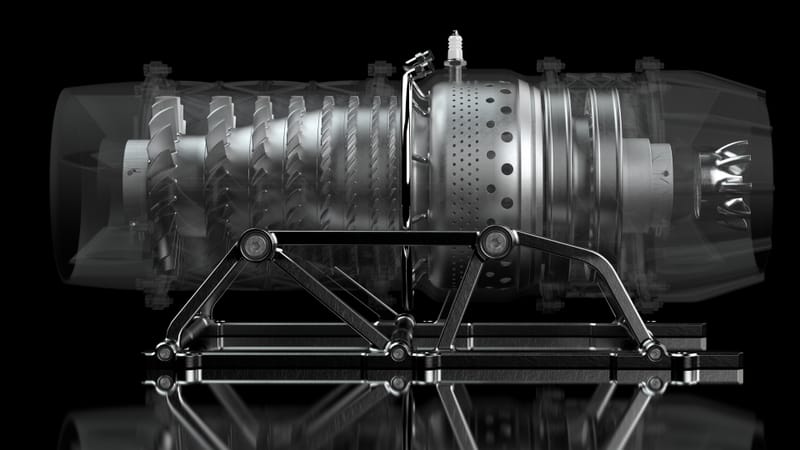

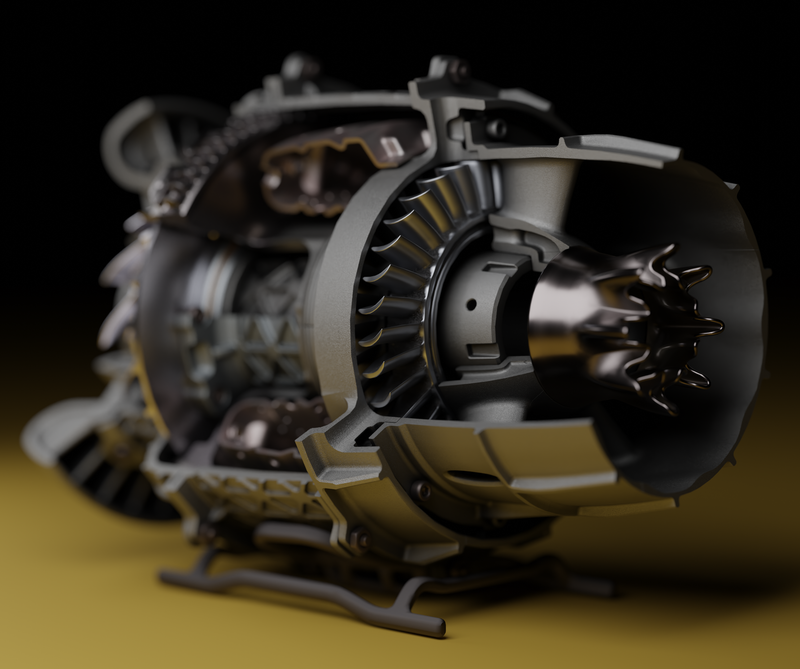

Read MoreOnly entry progress has been made on this model so far, but this is the next iteration, applying a 2-spool design consisting of a spool for the fan and another for the compressor. The size envelope is also roughly 300mm diameter x 600mm long - so still a microjet for simplicity.

Read MoreA supercar based off the Brabham BT62 modelled for the aim of being a game asset for a sci-fi game. Modelled in SW, cleaned up & unwrapped in Blender, textured in Adobe Substance Painter, rendered in SW Visualize. The result is ~15k tri PBR textured car model.

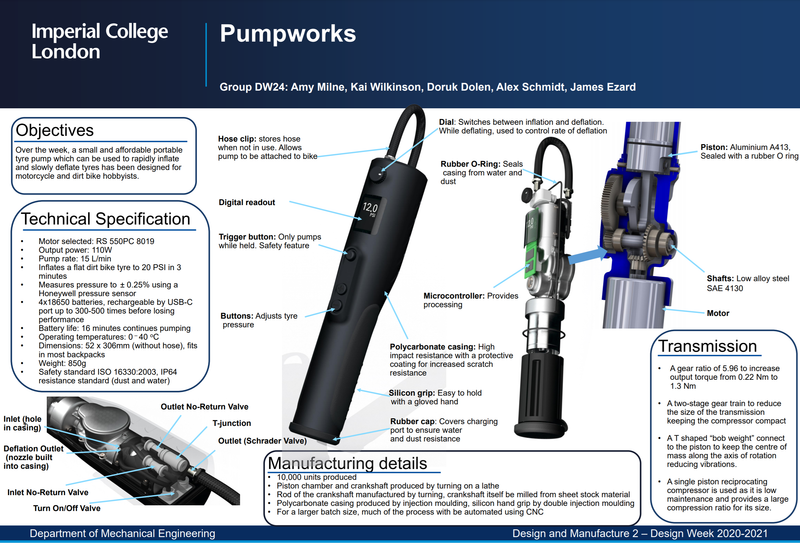

Read MoreElectric air piston pump. Produced in a team but CAD model completely made by myself and design lead by me. Worked collaboratively on design aspects and calculations to determine pump performance, life, required transmission ratio, etc.

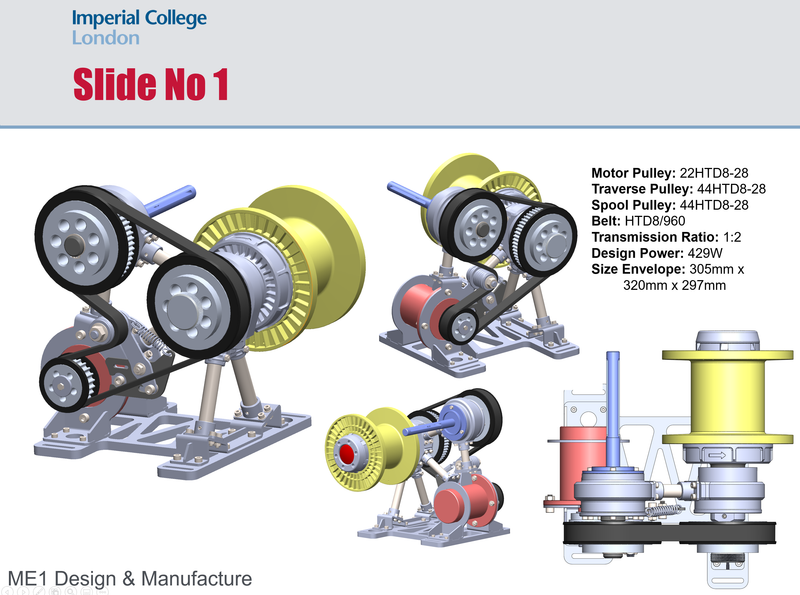

Read MoreIndividual transmission project during ME1.

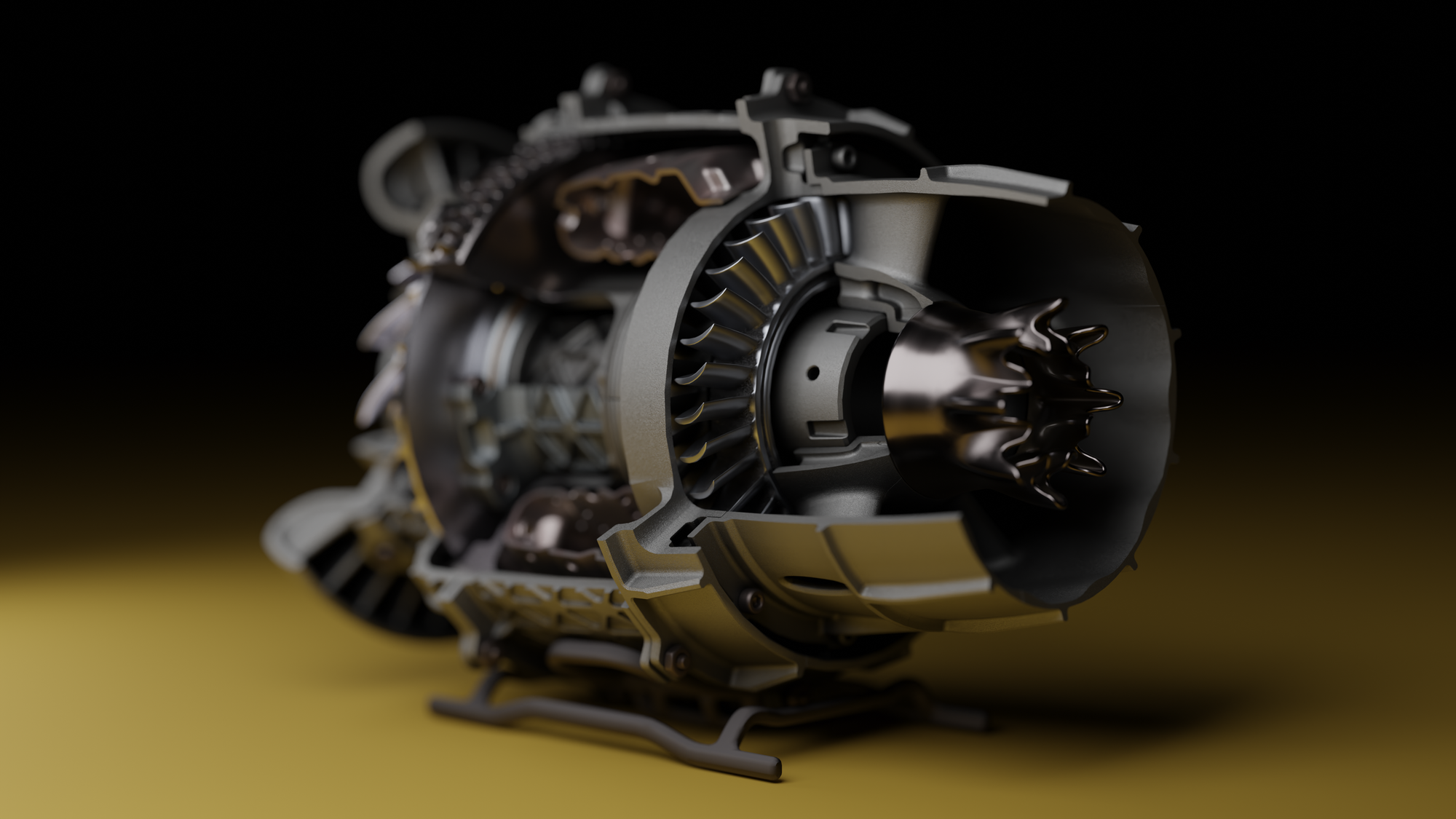

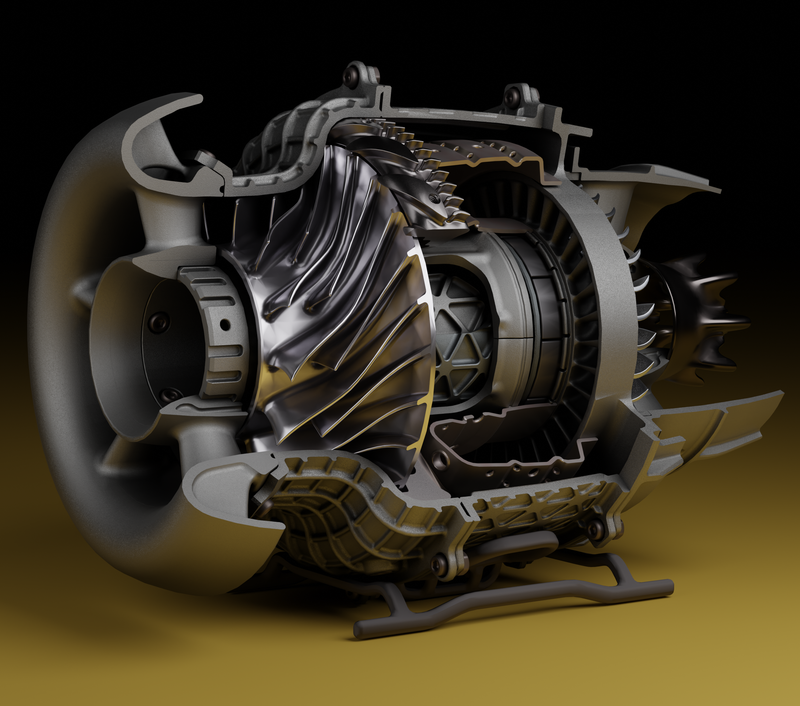

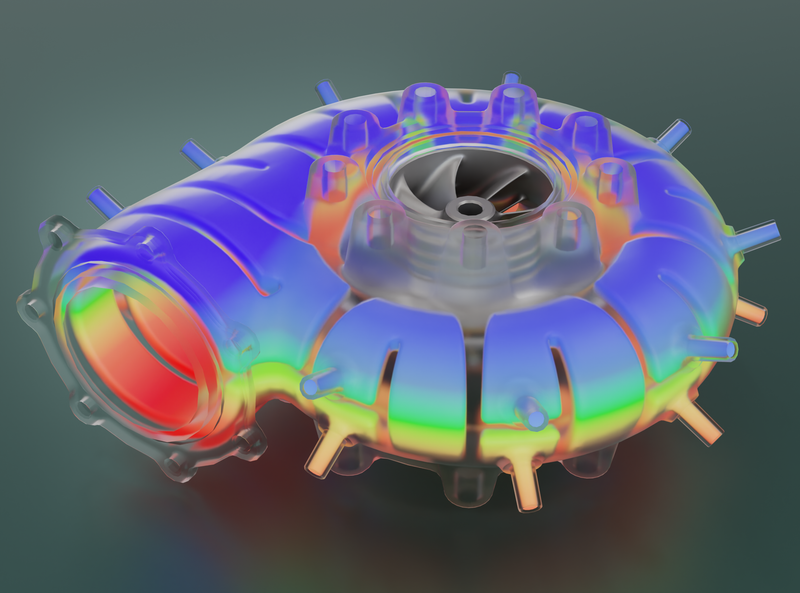

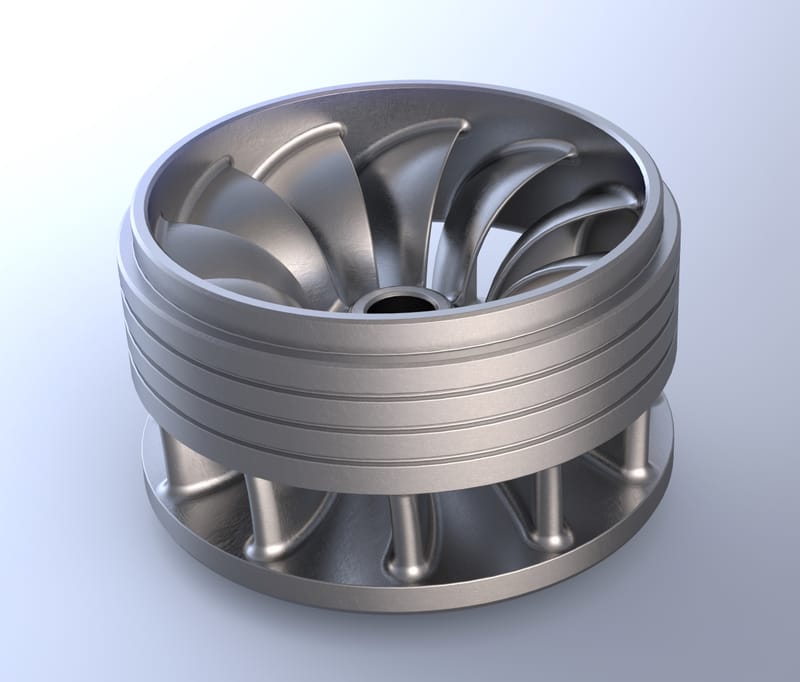

Read MoreA small centrifugal turbojet featuring a hollow bore and drum rotor. This has been designed for the intention of being a 3D printed model rather than a potentially functional design.

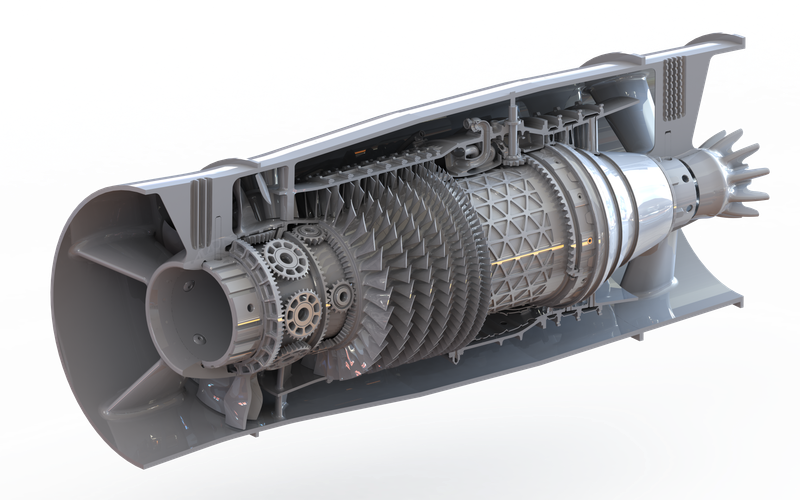

Read MoreThis is a further iteration of the existing ESE jet turbine but instead incorporates a geared fan stage as well as other features. Note that this design is incomplete at this stage.

Read MoreAn investigation to design a radical type of jet engine with the aim of it being a feasible device. Although this type of turbomachinery has been attempted before by NASA, I have changed the idea of the design by keeping the bearings on the inside edge of the blisks rather than the less-viable option of leaving them on the outside edge. The design I make here is of a microjet which too has its own set of challenges.

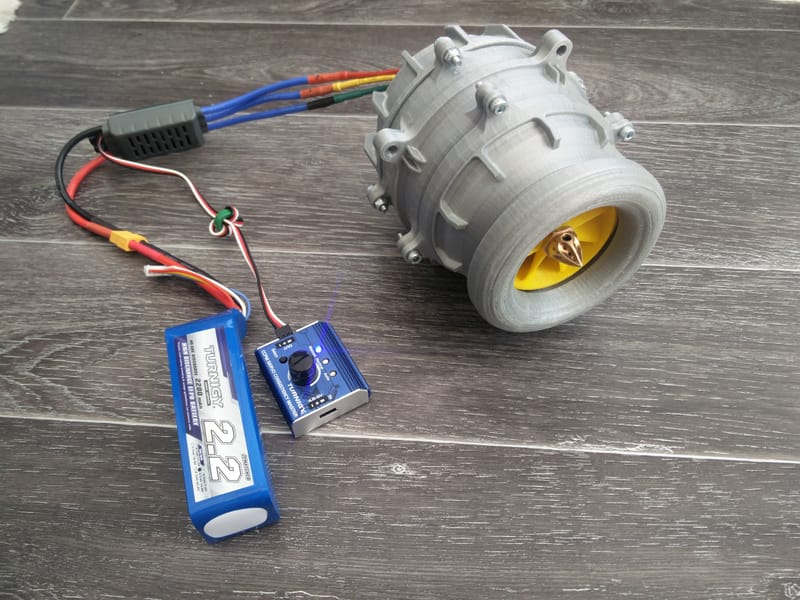

Read MoreThis was a project that I did in my own time to design a bladeless tower fan to understand both the engineering and physics that make this technology work. Using rapid prototyping, I 3D-printed the propulsion unit - the part of the device that propels air through and out of fan; this was done with the intention of testing the impeller, testing different iterations of the impeller the design in order to produce better performance. This project helped me gain skills in CAD, better understand in physics but also skills in testing, analyzing and iterating. I have made 3 iterations of the whole device, 7 iterations upon the impeller and 1 iteration of a component during real life testing.

Read MoreThis quadcopter project was actually used as part of Duke of Edinburgh Bronze under the "Skill" section; I did this project in Year 10. My aim was to produce roughly a 600mm diameter quadcopter complete with live camera feed. Sadly the project was plagued with a series of issues mostly with electronic component failure but it taught me how to troubleshoot and narrow down issues to work out what is causing the system to fail.

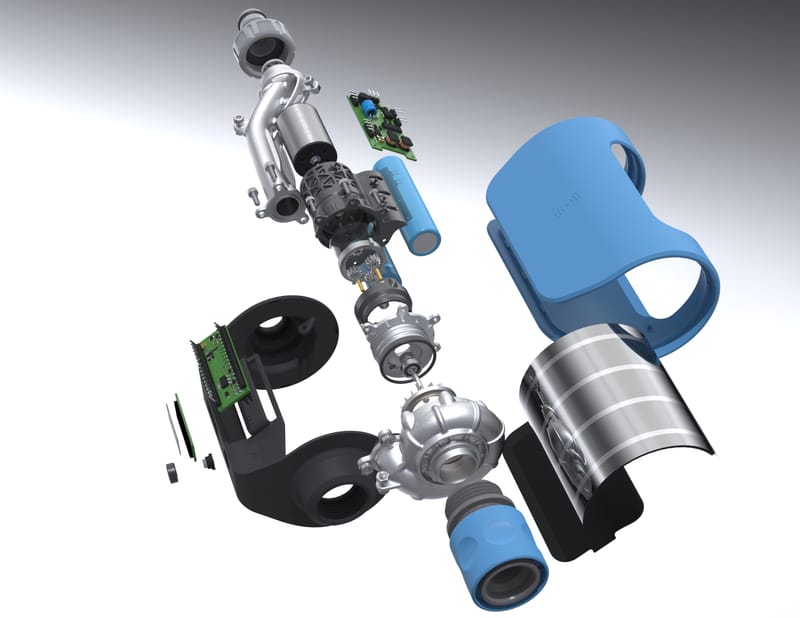

Read MoreThe project revolves around a smart water meter intended for the garden, that can be attached to a tap or anywhere in hose ducting. It will display both on the device but also on your phone your consumption but also the cost of it - the phone app is intended to also show other information and statistics. One of the key features of the device is to use the flowing water to also power the device, charging the battery - hopefully it is effective enough to be self-sufficient.

Read MoreMini-Projects

These are small projects and models that I have made. They are listed newest to last.

Fasteners that are completely dictated by input variables. Based off Accu fasteners for dimensions, it'll allow the user to quickly create new dimensionally accurate fasteners, by simplyl adjusting the variables in one place which proceeds to automatically adjust the rest of the model.. There are two toggles for level of detail. The threads are custom sweep cuts and are ISO-accurate, due to using official ISO documentation. All detailing features adjust automatically to the size of the fastener.

Read More3D-printed from nylon, this water-cooled pump would be used with boiling water as a working fluid. Whilst this project was ultimately no longer needed by the team, the cost and manufacturing restraints created unique solutions to the heat issue. The CAD techniques and ideation behind the cooling channels and the pump design was a fun challenge and expanded my skillset. These ideas of integrated cooling channels, made possible by 3D-printing, can be applied to numerous other applications.

Read MoreThis is the stage where I start making the shift away from SOLIDWOKRS Visualize and begin rendering projects in Blender instead.

Read MoreThe Francis turbine runner is a fair complex piece of geometry and being able to model this helped me learn how to use certain features in Solidworks - Boundary boss extrude in particular.

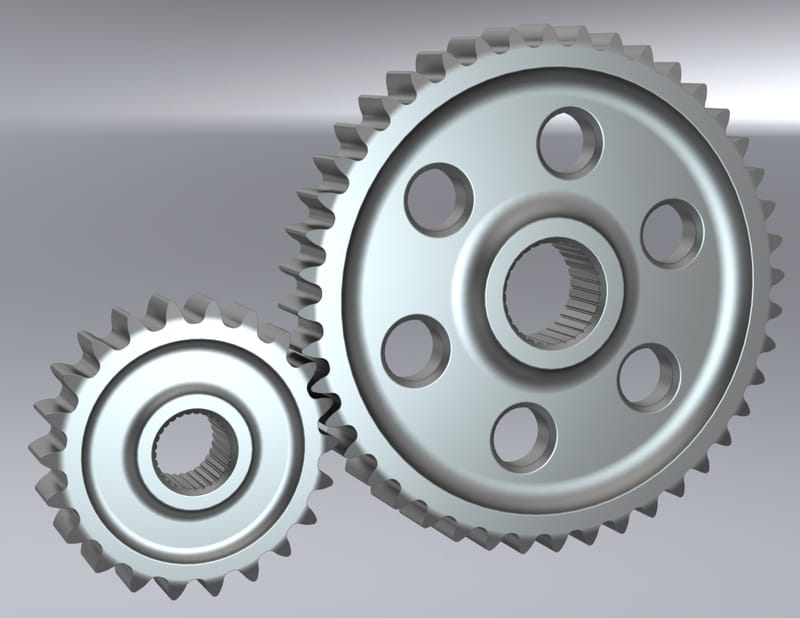

Read MoreJust a short gear animation of a simple 2:1 gear ratio. This was done quickly in 720p.

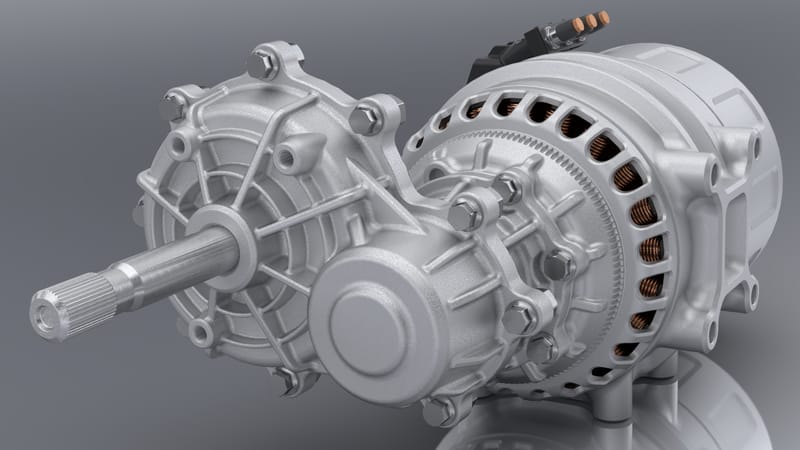

Read MoreOriginally, just wanted to make a simple 2:1 gear ratio animation for my A level project but ended up making a gearbox body shell and an electric motor to accompany it.

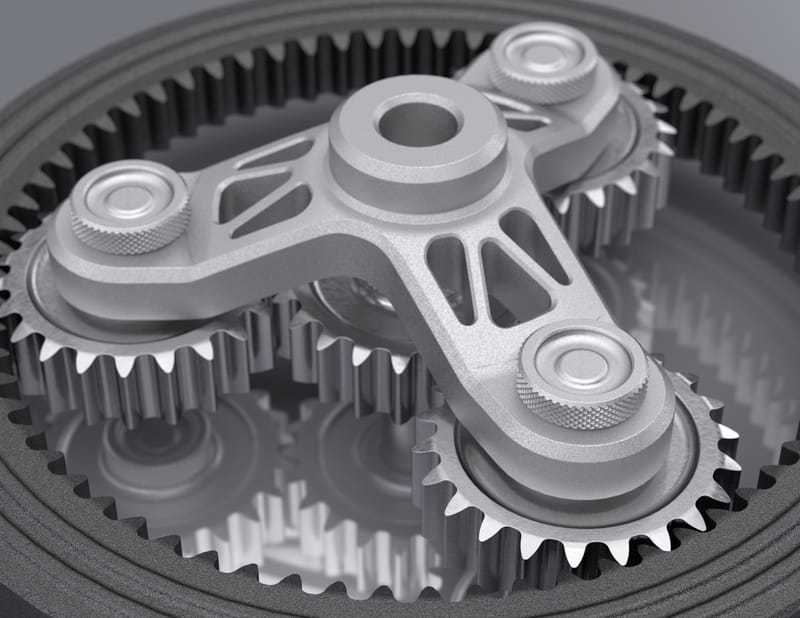

Read MoreI animated planetary gears for my A-level project.

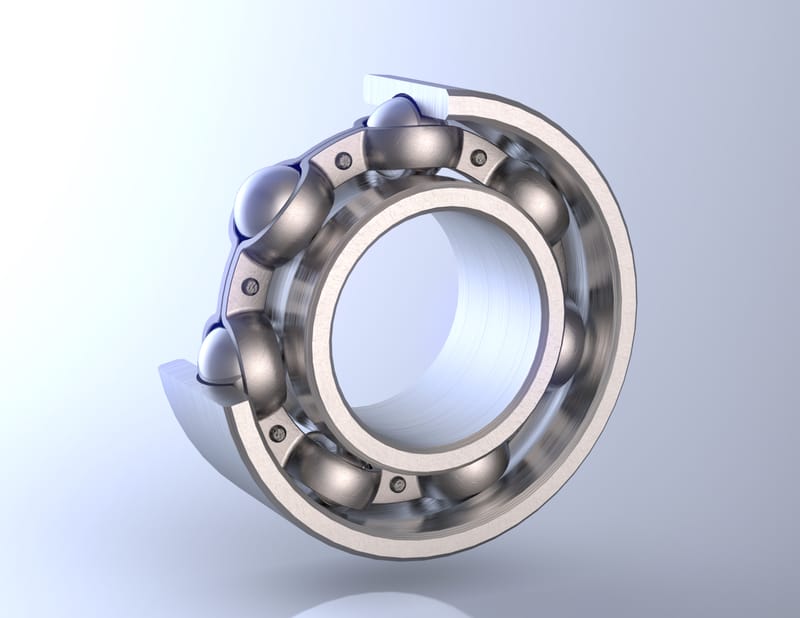

Read MoreSmall radial ball bearing that was used in the RC car differential. The ball bearing cage uses a stamped metal design. Trying to get the stamped piece to perfectly fit with the ball bearings was possibly the most difficult element of this model.

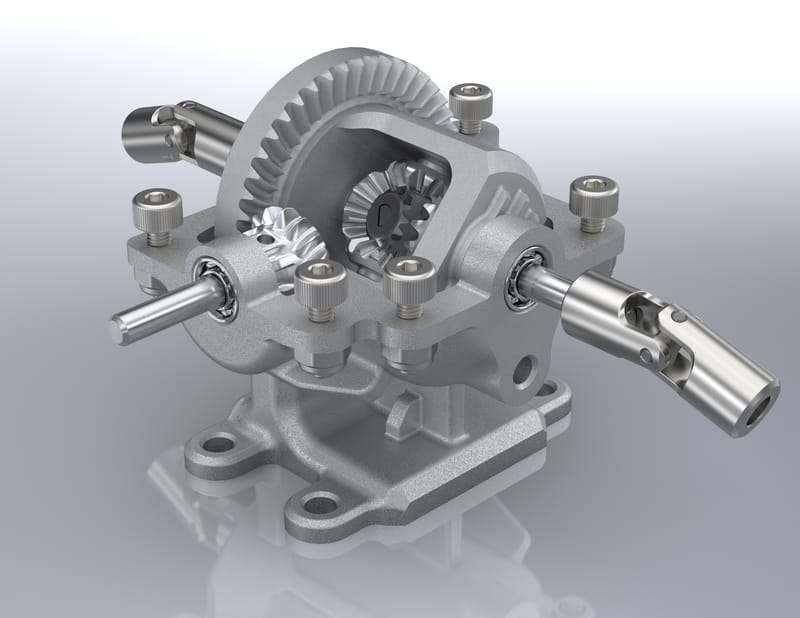

Read MoreI designed this differential for a RC car project that my friend and I were doing. This is a working differential allowing for one wheel to go slower than the other. The gear ratio of the differential is 1:3.

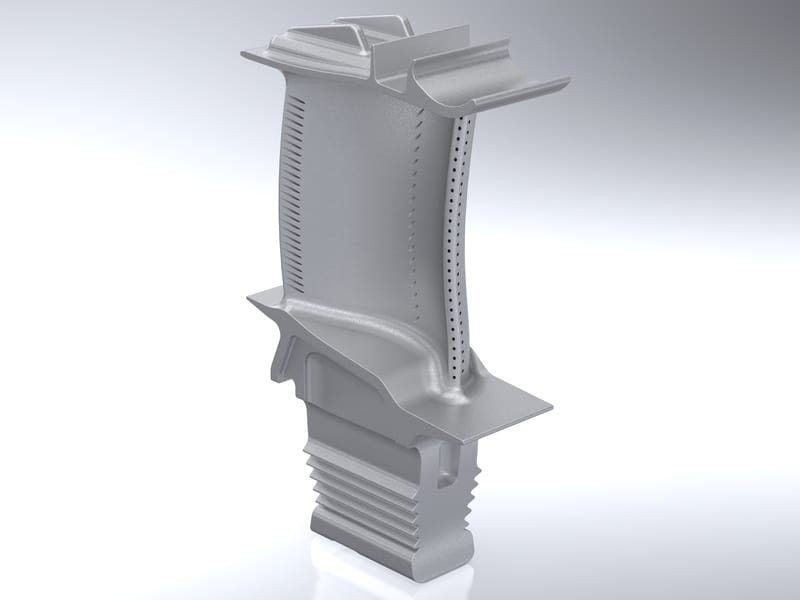

Read MoreA simple turbine blade with film air cooling.

Read MoreThis multi-tool pliers is complete with 18 different tools all ensuring that you'll be carrying anything you could possibly need to use.

Read MoreSimply a test model that I quickly put together to learn how to make a knurled surface and to play around with lighting in SOLIDWORKS Visualize.

Read More